MEASURING OUR IMPACT TO ACT BETTER

At SIPH, we are convinced that we have a role to play in the fight against global warming. This is why since 1997, we have made the environmental subject a major focus of our sustainable development policy.

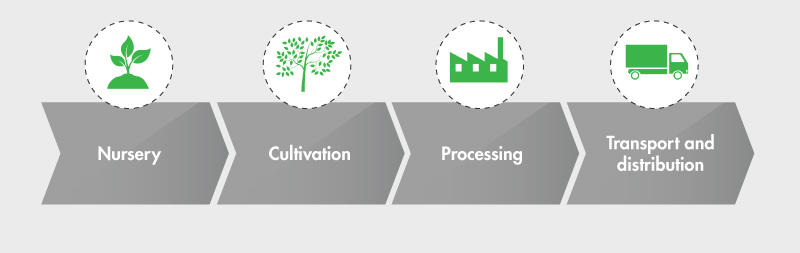

Because it is essential to act, to evaluate and quantify our impact, we regularly measure our GHG emissions on our rubber operations in Côte d'Ivoire, Ghana, Liberia, and Nigeria, from the value chain ranging from plantations through to factory processing and export to international markets.

Emissions reporting follows the Product Life Cycle Assessment methodology established by the Green House Gas (GHG) Protocol. The emissions calculator we use was developed by MEO Carbon Solutions, an environmental consulting company, in collaboration with our industrial partners SOCFIN and Michelin.

Download the full press releaseOUR GREENHOUSE GAS (GHG) EMISSIONS

SIPH has been committed to a ZERO DEFORESTATION and ZERO BURNING approach since 2016 and follows the HCV/HCS (High Conservation Value / High Carbon Stock) methodology for all its extensions. Emissions related to land use change during the creation of our industrial plantations are therefore not considered in this 2023 report, nor are emissions related to historical changes in land use by small growers with whom we buy our rubbers.

Our total emissions per ton of natural rubber produced in 2023 = 362 CO2 equivalent per T.

- Compared to 354 CO2ep/T of TSR

- We recorded a 2% rise in total emission per ton against 8% rise in production

- 50% of emissions from direct energy production, i.e. Scope 1. An effect of our ramp up in volumes in 2023.

- 21% emissions fall in Scope 2; this is indirect purchase of energy from the grid.

- 29% of emissions are in Scope 3; attributed to upstream and downstream transport and material acquisition across all systems.

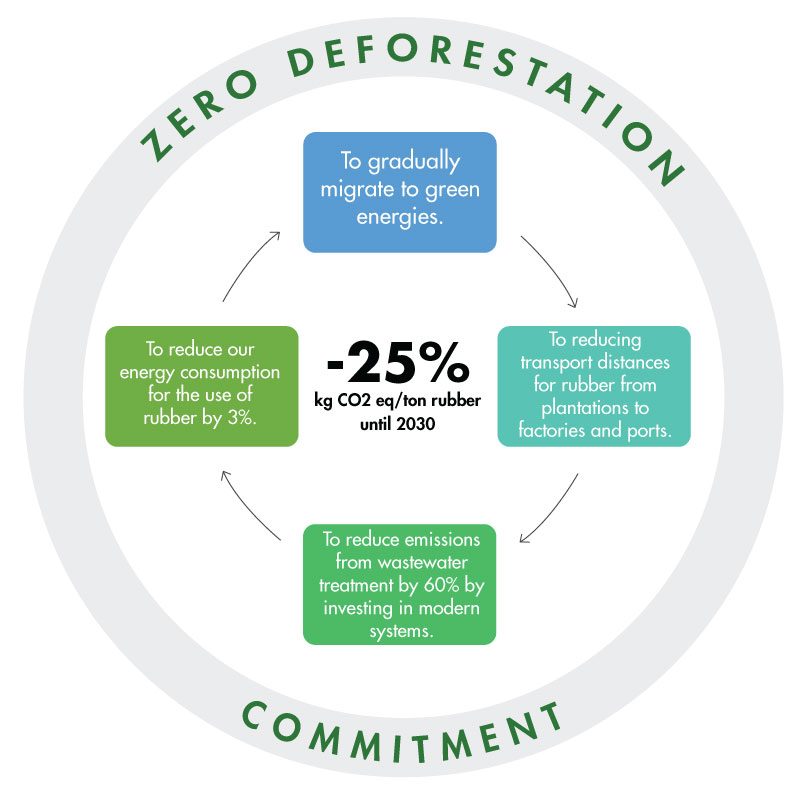

Our actions to reduce the main sources of GHG (Greenhouse Gas) emissions

Scope 1: direct emissions

To reduce the environmental impact generated by our activity, since 2019 we have implemented a plan to drastically reduce the use of phytosanitary products and chemical fertilizers in plantations. These initiatives have enabled the storage in the soil of around 50 T of CO2/ha.

We are continuing this responsible management by reducing by 2030 approximately 20% of the use of fossil fuels when replanting our rubber plots and 3% per year of energy consumption in our factories in transformation.

Calculations also showed that our machining effluent treatment systems are the source of nearly 11% of greenhouse gas (GHG) emissions. This is why it seems urgent to us to reduce these emissions, by capturing the methane emitted and by moving towards modern systems such as activated sludge.

Scope 2: énergy consumption

Rubberwood at the end of its life is already transformed into chips to fuel boilers or recycled into lumber, following the example of the SAPH BONGO integrated farm unit in Côte d'Ivoire.

A gradual plan to replace high CO2-emitting electricity sources with green options has been initiated, and solar power generation pilots will be installed on our sites by 2025.

Scope 3: indirect emissions

A working group has been set up to rethink our method of transporting rubber. This implies favoring modes with low CO2 emissions for our movements of rubber, from the plantations to the factories, and from the factories to the ports of embarkation.